Compressed air is used in railway and rail transport, for example, for opening and closing doors or the braking system. Safety and reliability are therefore the most important criteria for compressed air systems in this area. Because the systems are used outdoors, they are exposed to fluctuating temperatures. The compressors must be able to withstand temperatures ranging from +40° in summer to -20° in winter without any problems. And because of the small space required in a train or other vehicle, the compressors must be compact and space-saving. ALMiG has already implemented a large number of projects for these high requirements and developed individual solutions for well-known customers.

Product range

From compressors to air dryers and all accessories - ALMiG develops, produces and distributes all main components for the air supply system in vehicles:

Compressors

- Screw compressors and piston compressors

- Oil-free compressors

- Modular, weight-optimised and reliable subsystems

- Low life cycle costs

- Low noise and vibration

- Quality "Made in Germany

Air dryers

- Single and dual chamber systems for dry and clean air

- Safety and performance of all downstream systems

- Fail-safe even at extreme temperatures

Engineering

- Customised design and integration

- Maintenance-friendly and energy-efficient

- Encapsulated and sound-insulated systems for underfloor installation

Accessories

- Filtration systems

- Fire detectors and extinguishing systems

- Pressure switch

- Condensate collectors

- Safety valves

Quality

At ALMiG, the quality of the products has a high priority. State-of-the-art manufacturing technologies, highly developed testing technology and a comprehensive quality management system enable us to ensure and constantly improve our reliability.

As a manufacturer of air treatment systems, we produce system components that must work reliably to ensure vehicle safety, which is why quality plays a central role in ALMiG's corporate philosophy.

IRIS-certified company

For railway technology suppliers, the IRIS quality standard is becoming increasingly important, as the major manufacturers are increasingly requiring this certification for A-suppliers. ALMiG has been IRIS-certified for years and therefore meets the most stringent quality requirements of the railway industry, which go far beyond the normal standards. The IRIS standards are recognised by all major railway manufacturers.

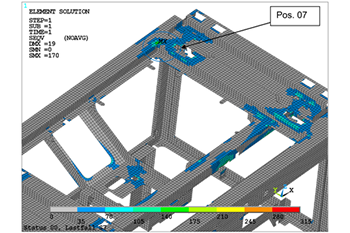

FEM analysis

In the ALMiG FEM analysis, the load cases are simulated for all frame constructions of the railway compressors and a detailed FEM model is calculated. The static load cases were specified according to DIN 12663 for passenger vehicles of category III (underground and suburban railway vehicles).

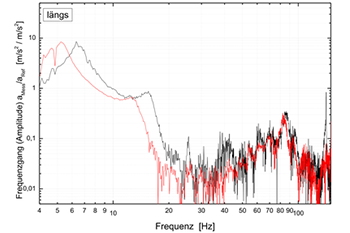

Vibration test / vibration and shock test

In the vibration and shock test (shaking test), the life cycle of the air generation unit is simulated. This is done under extreme conditions in specially designed test centres to simulate the use of the systems for far more than 30 years. Here, the theoretically determined values from the FEM calculation are again confirmed in practice. The design is carried out in accordance with DIN EN 61373.

Climate chamber

In specially designed climatic chambers, our compressors and systems are tested for suitability even under extreme climatic conditions. The climatic test serves as practical proof of the general behaviour of the system at temperatures ranging from -50°C to +70°C. Special emphasis is placed on minimising the effects of temperature on the overall system and ensuring functional safety during operation.

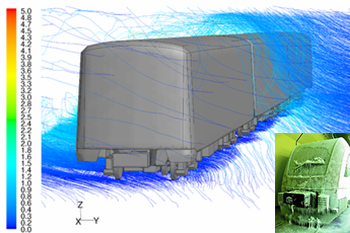

Snow simulation

To simulate winter operation, ALMiG products are subjected to a snow simulation in the wind tunnel. Snow particles with the expected particle retention time in the underbody area are simulated, for example, when driving forward at normal speed on an open road with wind and snow falling from the front. The amount of snow introduced corresponds to a snow height of more than 30 cm/hour.

Salt spray test for corrosion testing

In order to test the high-quality coatings on our products, the units are subjected to a salt spray test. Here, the compressor is extensively tested for a test duration of 6 hours to well over 1000 hours, depending on the customer's specifications, in order to prove a long service life of the components even under extreme, corrosion-promoting atmospheric conditions.

RAMS / LCC

ALMiG products are developed with a special focus on reliability, availability, maintainability and safety. We also prove this daily to our customers worldwide. Detailed information is provided to our customers in order to meet all RAMS requirements. In this context, special attention is paid to minimising life cycle costs as early as the tendering phase.