COMPRESSOR SERIES G-Drive T

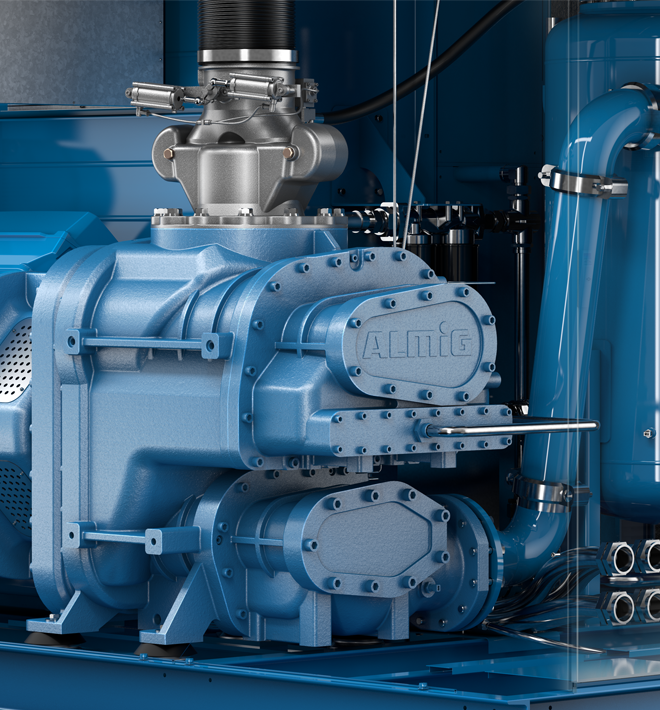

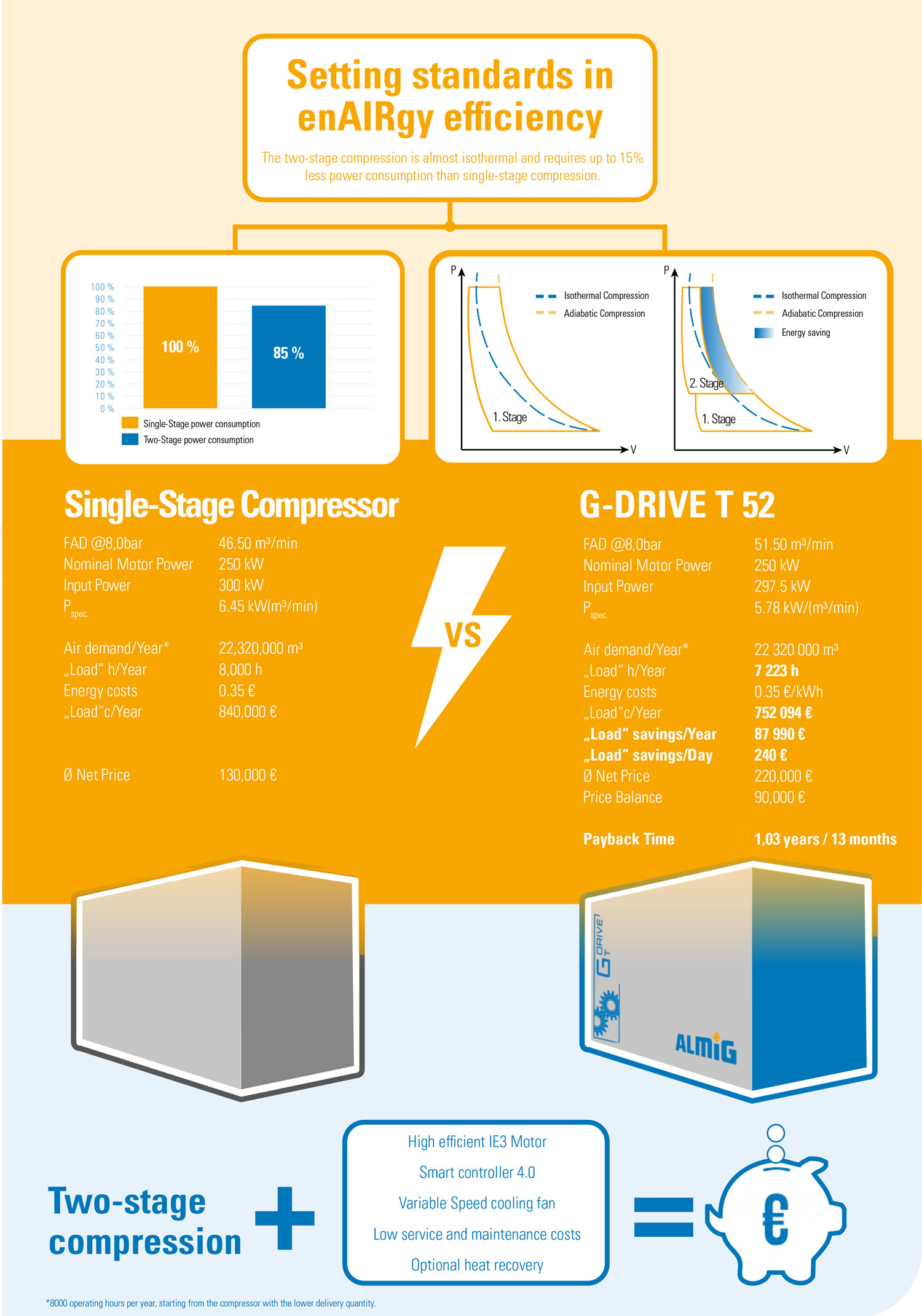

Two combined, optimally matched compressor stages achieve a specific performance that is second to none. The G-Drive T compressor series from ALMiG thus delivers a higher volume flow with simultaneously lower motor power consumption compared to equivalent single-stage compressors commercially available.

In addition to efficiency, low speeds and a lower internal pressure difference in each stage also increase the service life and reliability of the compressor unit.

First-class efficiency paired with lower noise development make two-stage screw compression so interesting for industrial compressed air supply.

Advantages:

- The high efficiency of the compressor can achieve high energy savings and reduce the life cycle costs of the system

- In some cases, energy savings of well over 15 % compared to single-stage compression

- Durable and reliable

- Low differential pressures

- Low heat load

- Easy maintenance and service

The screw compressors of the G-Drive T series offer all these advantages and add a small footprint due to the sophisticated design.

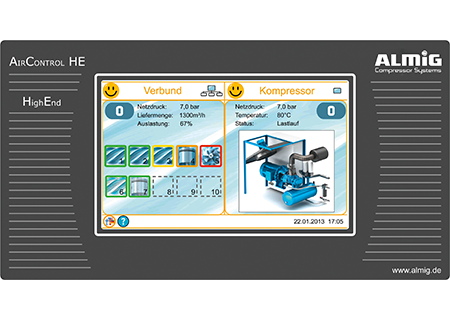

In terms of Industry 4.0, the compressor's control system has all the prerequisites to participate in the company's internal communication or to be monitored externally via cloud service.

The unique stage design integrates the first and second stages into one compressor unit. The rotors of each compressor stage reach the optimal speed through the gear drive. Efficient compression is achieved by using a cooling oil mist for intercooling. This controlled amount of oil simultaneously enables the pressure dew point to be undershot in order to exclude condensate failure in the second compressor stage. A cumbersome and expensive separate intermediate cooling can thus be avoided and reliability is increased at the same time.

Technical information

G-Drive T | Volume flow according to ISO 1217 (Annex C-2009) | Rated motor power | Length | Width | Height | ||

|---|---|---|---|---|---|---|---|

Model | at 8 bar | at 10 bar | at 13 bar | kW | mm | mm | mm |

| m³/min | m³/min | m³/min | |||||

| 20 | 17,69 | 16,28 | 14,28 | 90 | 3250 | 1800 | 1800 |

| 24 | 22,42 | 19,63 | 16,30 | 110 | 3250 | 1800 | 1800 |

| 26 | 26,15 | 22,42 | 16,65 | 132 | 3250 | 1800 | 1800 |

| 28 | 26,67 | 22,73 | 21,19 | 132 | 3685 | 2120 | 2000 |

| 34 | 32,39 | 28,67 | 25,71 | 160 | 3685 | 2120 | 2000 |

| 40 | 38,91 | 34,89 | 30,7 | 200 | 3685 | 2120 | 200 |

| 42 | 41,1 | 36,2 | 31,0 | 200 | 4531 | 2250 | 2438 |

| 52 | 51,5 | 454,5 | 40,2 | 250 | 4531 | 2250 | 2438 |

| 64 | 62,7 | 55,4 | 50,2 | 315 | 4531 | 2250 | 2438 |