Optimise compressed air supply and save energy costs

Energy is becoming increasingly expensive and is having an impact on the competitiveness of companies. To provide cost relief, more and more companies are turning to energy-efficient systems. The international energy management standard ISO 50001, which was introduced in June 2011, is also playing an increasingly important role. Many companies - regardless of whether they are small, medium-sized or large enterprises - are having themselves certified according to this standard. However, many are not aware that compressed air, which is the largest energy source in industry after electricity, also has a high potential for savings.

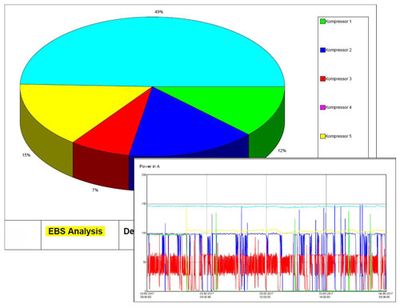

In order to uncover possible energy savings in compressed air generation and consumption, ALMiG has developed a special procedure: The Energy Balancing System - EBS for short.

Up to 40 % energy saving potential is hidden in almost every compressed air station. To detect expensive weak points in your system and optimize your compressed air supply, we take a critical look at all components from the compressed air generator to the compressed air consumer.

Compressed air generation

Energy costs account for up to 90 % of the operating costs for compressed air generation.

Modern, speed-controlled energy-saving compressors save up to 25 % energy.

Compressor controls

Intelligent control systems monitor and optimise the entire compressed air station and help to reduce costs and increase operational reliability.

Compressed air preparation

Every application requires special treatment:

- Too much treatment = unnecessary energy and operating costs

- Too little preparation = loss of quality or even production downtimes

Heat recovery

Up to 94 % of the energy used to generate compressed air is converted into heat and can be used in a variety of ways, e.g. as heating or service water.

The "3-step plan" of ALMiG's Energy Balancing System (EBS System) solves your energy problems. This energy balancing system shows how your overall compressed air system can be operated with maximum energy efficiency and how the power guzzlers can be eliminated.

The "3-step plan" of ALMiG's EBS system consists of the three steps:

- Measure

- Analyze

- Simulate

The benefit of a compressed air consumption measurement with subsequent simulation is obvious:

- The overall compressed air system becomes transparent.

- Weak points are revealed.

- A variety of tabular and graphical representations support your decision making.

- Effects of changes in the compressed air station can be simulated.

- This allows you to run through all scenarios and develop the optimal solution for your situation.

Individual consulting for cost optimization of a compressed air station can only be done on the incorruptible basis of previously obtained information and the simulation of future plant or compressed air overall concepts.

Reason enough for the ALMiG specialists to determine your current compressed air consumption with the help of an exact consumption measurement, in order to then work out an optimal system solution together with you.

Leakages in the compressed air system

The results of the EBS measurement can also be used to determine whether your compressed air control system is leaking.

Did you know that the average leakage rate of a compressed air station is almost 30%? Leakage points in the overall compressed air system, i.e. in the distribution line or at the various connection points to the consumer, represent a high cost factor. The leaks act like nozzles from which the air escapes at enormous speed.

Since escaping air is invisible and odorless and poses no direct danger, it is usually not treated with similar attention as, for example, a leak in a water pipe. The increased volume flow demand caused by leaks leads to higher energy costs for compressed air generation.