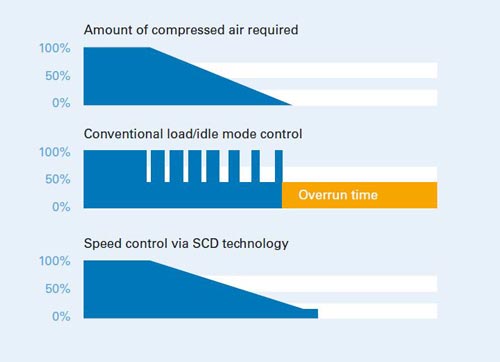

Analyses show that conventional compressors are only utilized to approx. 50-70% on average and the maximum delivery volume (100% full utilization) is only required at peak times. It is precisely in this range, i.e. below full capacity, that the main area of application and the strengths of speed-controlled energy-saving compressors with SCD technology lie.

SCD technology stands for speed controlled direct drive and is a concept in which the advantages of SCD speed control are implemented economically in conjunction with an SCD direct drive and a highly efficient integrated SCD frequency converter.

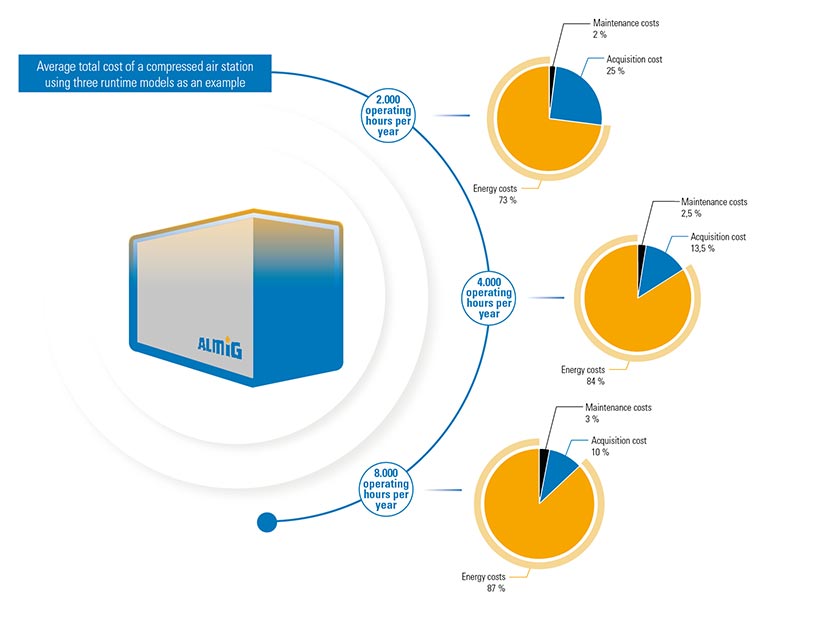

Average total cost of a compressed air station

Energy costs are the most important factor in a compressed air station. Despite ever-increasing energy prices, up to 40% more energy is still consumed today than would actually be necessary.

One of the reasons for this is the generation of compressed air, produced exclusively by standard compressors with fixed speed.

Conventional or standard compressors with a fixed motor speed can only cope with the varying air demand within a production by load-idle control or by proportional or suction throttle control. However, with both types of control, enormous power losses occur if they are operated below the maximum load.

- By varying the motor speed, the speed-controlled screw compressors only draw as much power as is actually required to generate the required volume of compressed air.

- By precisely adapting the volume flow to the respective compressed air requirement, costly idle times are reduced to a minimum (idle means: approx. 25 - 30% total power consumption of the compressor without generating compressed air).

Constant mains pressure

The speed-controlled screw compressors keep the once programmed final compression pressure constant within a pressure band up to +/- 0.1 bar and this also with changing compressed air demand. In this way, a low final compression pressure is possible and energy can be saved.

Free choice of optimum operating pressure

The speed-controlled screw compressors offer the possibility of freely selecting the operating pressure between 5 and 13 bar in increments of 0.1 bar. Optimum adaptation to all on-site conditions, e.g. day and night shifts, can be achieved in a matter of seconds. This ensures maximum flexibility and efficiency across a wide range of applications - even for future plant expansions.

Energy-saving start-up without power peaks

Thanks to the use of the fully integrated SCD frequency converter and the innovative and highly efficient SCD motor, the speed-controlled screw compressors are also characterized by the fact that they realize a soft start of the motor due to the system without causing expensive current peaks.

The current consumption of the SCD motor is always below the rated current during start-up.

Your energy-saving potential in figures:

Compared to a standard compressor, savings can be achieved at the following points when using an "energy-saving compressor" with speed control:

- Avoidance of idling

- Reduced unloading frequency

- Reduced compressed air losses (due to reduced unloading frequency)

- Pressure belt optimization (constant mains pressure)

- Direct drive (avoidance of drive losses)

- Leakage reduction

The following example illustrates the savings potential inherent in the use of variable speed screw compressors.

Example:

Screw compressor with an installed motor power of 60 kW

a load share of 70%

4000 operating hours/year

10 bar operating pressure

energy costs of 6 cents/kWh.

Result = € 5,400