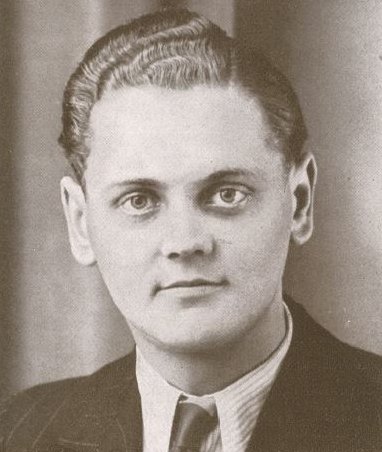

Adolf Ehmann was born on November 23, 1895 in Untertürkheim near Stuttgart, the son of a master shoemaker.

The drawing board and compasses were his most familiar tools from an early age. He devoted every free hour to technical drawing and his own designs. At the age of 13, he began an apprenticeship as a mechanic and became a master mechanic in 1922.

On October 1, 1923, he went into business for himself and founded his own company - at the time of hyperinflation, which caused the currency of the time to collapse and wiped out everything he had saved up in one fell swoop. This did not stop the master mechanic Ehmann from his desire to become self-employed. He started working with an apprentice in a small workshop of 28 m2. In addition to individual parts such as gears and cogwheels, he produced complete devices such as air blowers and glass boron machines for watchmakers and belt cutters for saddlers. During this period of economic depression, Adolf Ehmann worked together with his apprentice and his wife at the lathe every day until the deepest hours of the night in order to create the basis for the realization of his plans through wage labor.

As motorized traffic became increasingly important, Ehmann and his employees built air pumps for car tires and served automobile companies in the surrounding area. In addition, there were car lifts, compressors for gas stations or compressed air tools such as paint spray guns. In the post-war period, pneumatics, i.e. the execution of mechanical work and movement with the aid of compressed air, became increasingly important in industry. Compressors had to be able to do more and more. In the meantime, ALMiG supplies compressed air systems for all industries worldwide.

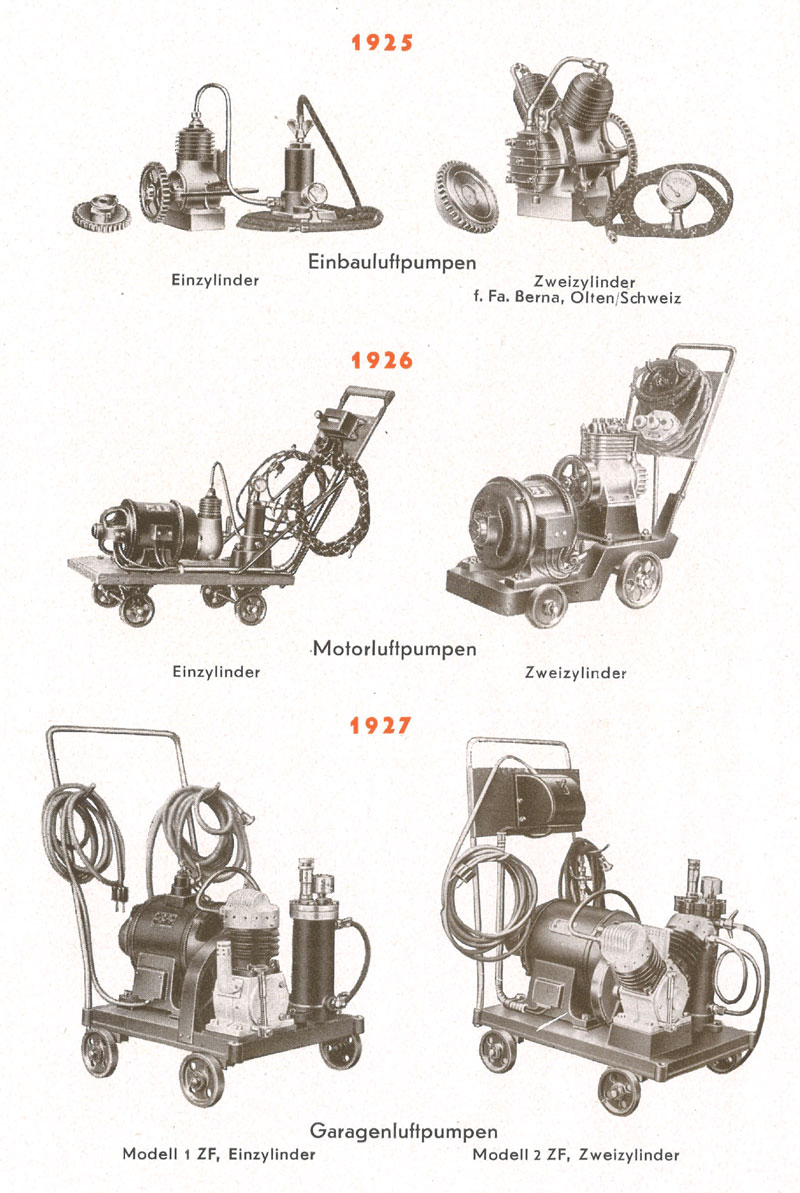

Company founder Ehmann had initially focused on a narrower customer base. Motorized transport had become increasingly important, and rubber tires had replaced wooden wheels on vehicles. After lengthy trials, he was able to start manufacturing built-in compressors and power air pumps in 1927.

Ehmann and his employees built air pumps for car tires and served automobile companies in the surrounding area such as Daimler-Benz.

In 1932, the first compressor unit was manufactured, soon followed by other models as well as two-stage units.

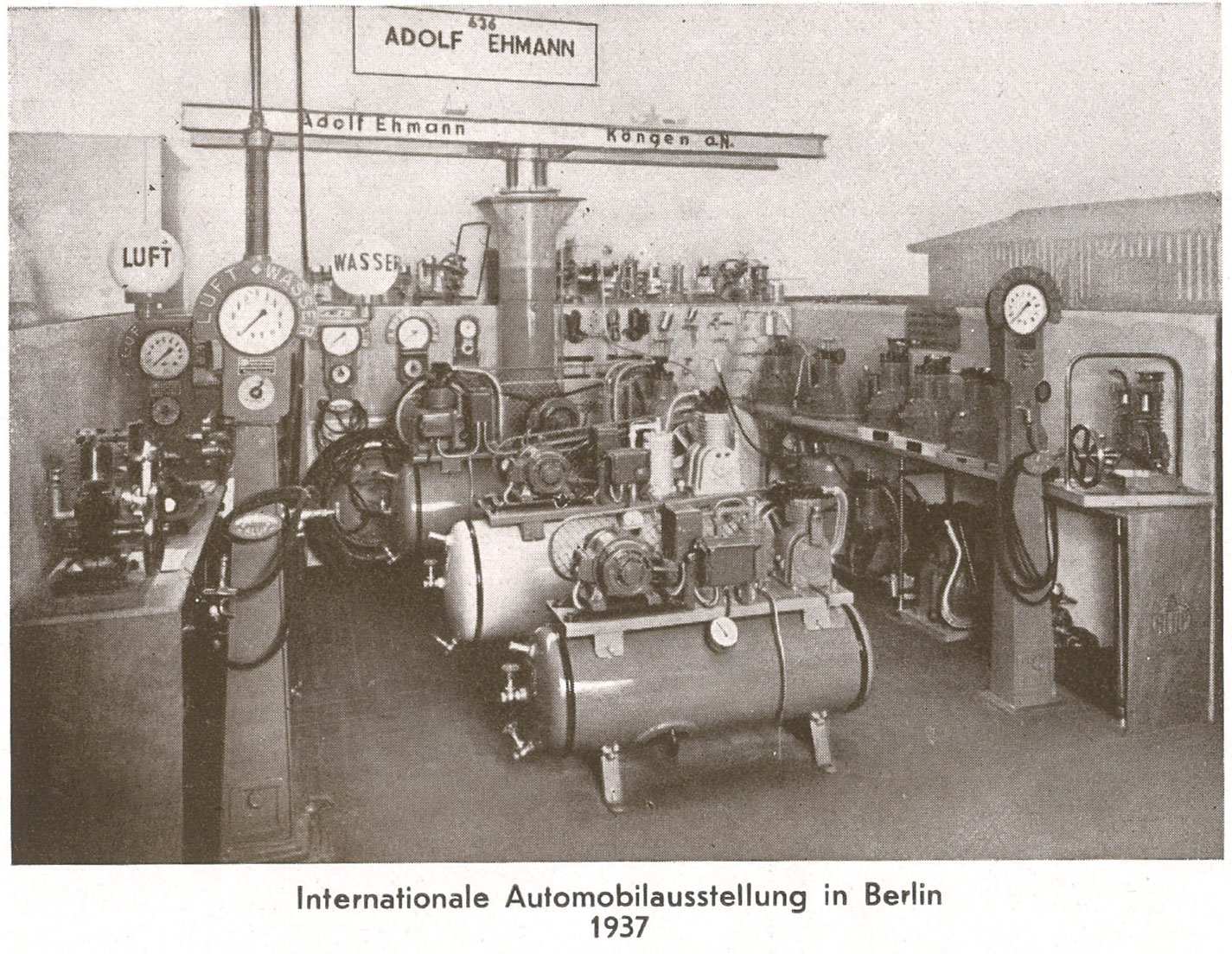

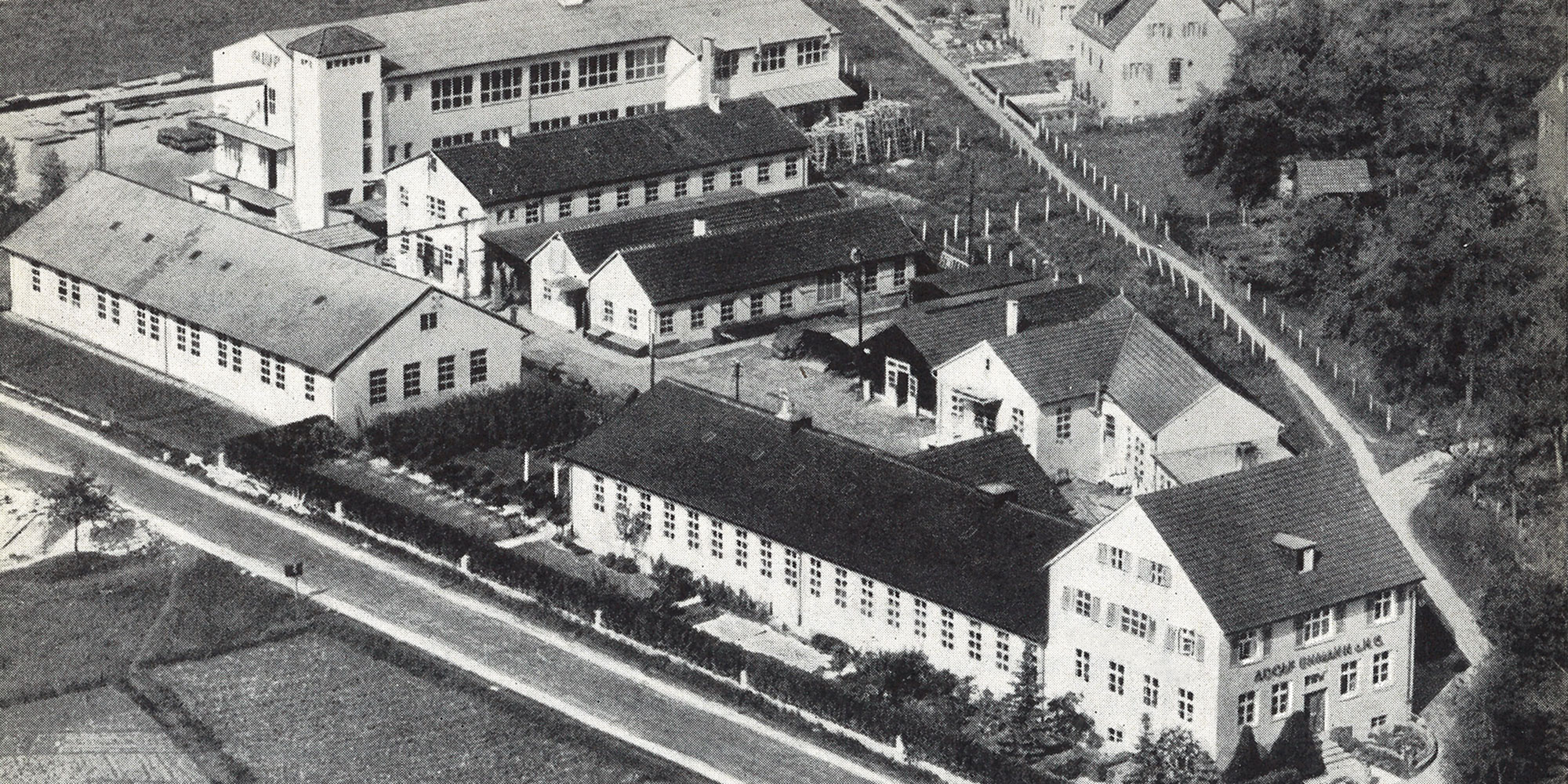

In 1935, Adolf Ehmann acquired building land in Köngen and started a new factory building, which was completed in 1937 and where compressors are still manufactured today.

In addition to the construction of the new factory, there was also progress and success in the technical field. At that time, 23 employees worked for Adolf Ehmann.

In 1937, the company exhibited its products for the first time at the International Automobile and Motorcycle Exhibition in Berlin. As a result, the products became known and sought after in domestic and foreign specialist circles.

The renewed visit to the Berlin Automobile Exhibition in 1939 was also a complete success. Very good sales were made for home and abroad, so that the delivery time was six months due to the good order situation.

Peacetime production could be maintained in full until 1941. After this date, a switch had to be made in part to armaments. Piston rod bearings were mainly machined on a contract basis, for which ten French prisoners of war were assigned to the plant. However, design and development work continued.

During the war, more and more male employees were drafted, so that only a very small number remained in the company. A large number of women were employed as replacements. The workforce at that time was 49 people.

Seven employees were killed in the war, and four employees were missing.

Apart from minor requisitions, the plant came through the war without any destruction.

On April 17, 1945, three days before the invasion of French troops, the plant was shut down.

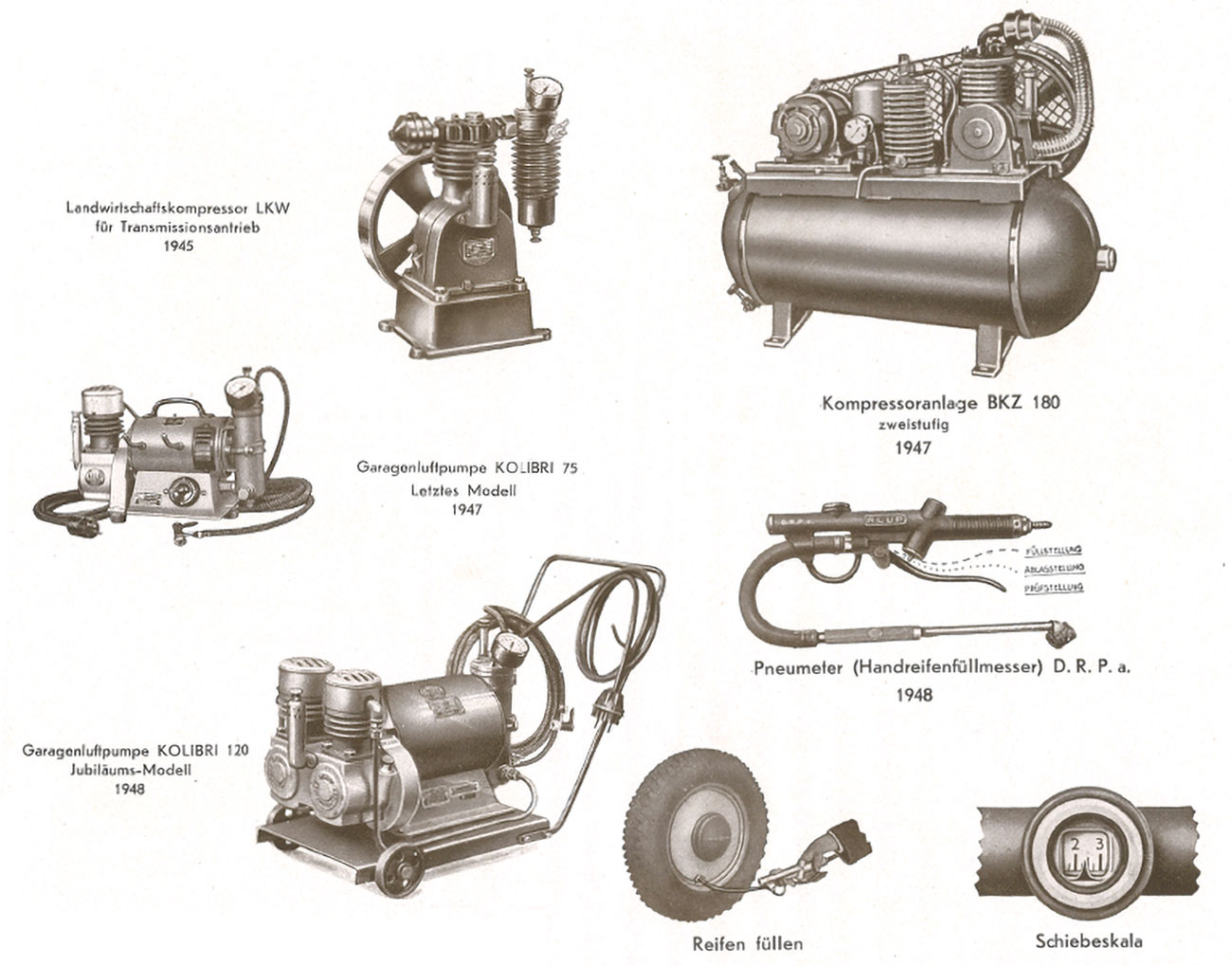

Work resumed in mid-July 1945, and at the same time there was a full-scale switch to peacetime production.

In 1946, a large number of orders were received, but due to the difficulties of material procurement, the delivery time was 18 months, which meant that no new orders could be accepted in 1947/48.

Nevertheless, in 1946 another factory building was erected and the production of new products started, such as car lifts, paint spray guns and paint spraying equipment, as well as fittings and after-cleaners.

The division of Germany into four occupation zones had a detrimental effect on the economy and there was a shortage of labor in many areas, resulting in a lack of the most necessary basic materials and components such as electric motors.

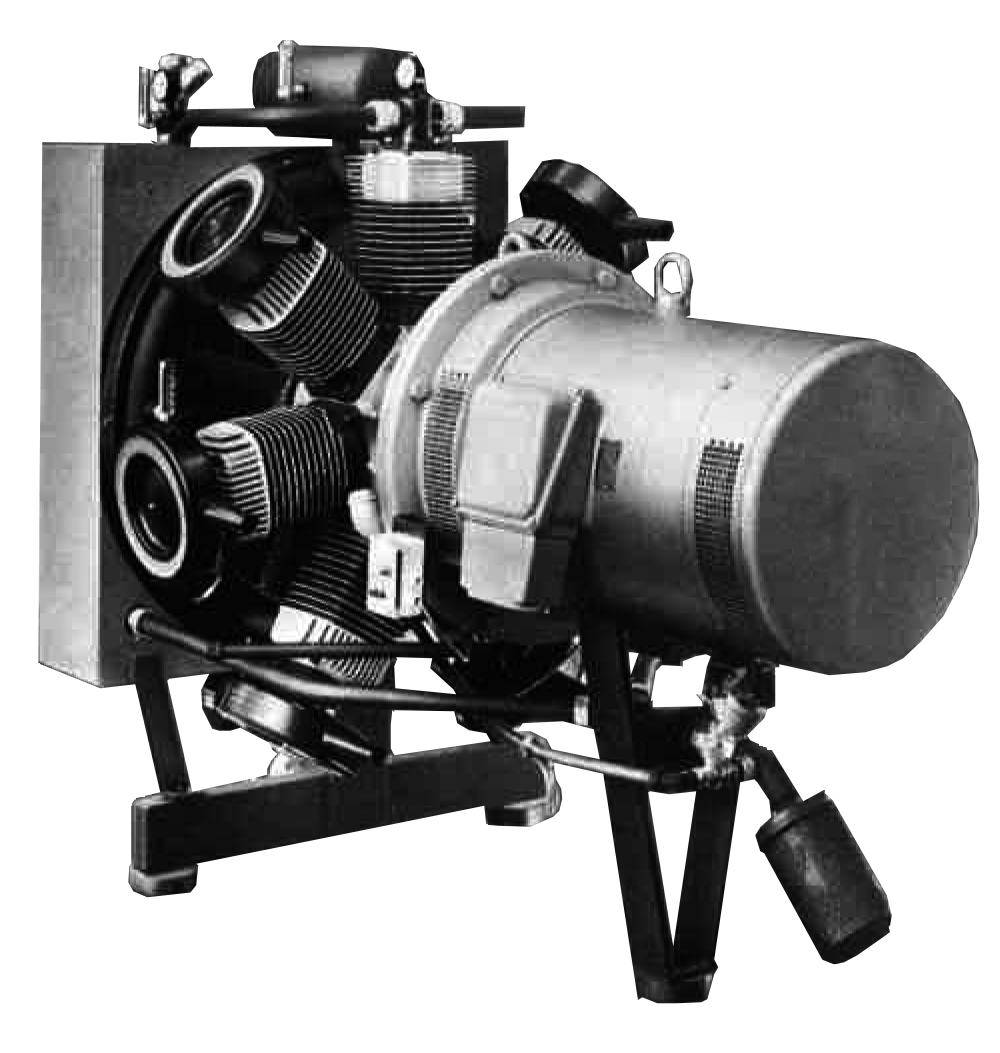

To counteract the closure of compressor manufacturing, built-in motors were added to the production program. This was a mammoth task, considering the difficulties in procuring the necessary equipment and testing devices as well as raw materials.

The son of the founder, Kurt Ehmann, excelled in building up the program and developing these motors to the point of series production.

By 1950, other products had been added: Car wash compressors, tire gauges, pressure gauges and new compressor units based on the modular principle.

In the 1950s, new buildings were gradually erected to provide further space for the final assembly of individual compressors and compressor units, as well as new storage facilities.

In 1959/60, boilers were also manufactured in-house.

In 1961, the company founder Adolf Ehmann dies. His son Kurt Ehmann takes over the sole management of the company.

In the 1960s and 1970s, the company expands and establishes subsidiaries and a sister company.

In 1973, the company has 150 employees and further development of compressors comes to the fore.

Thus, in the mid-1970s, the HL-Stern compressor is launched - a 7-cylinder in a star arrangement with 60 kW power and a delivery rate of 8.05 m3/min.

In 1980, the family business is acquired by the American Masco Group. Expansion abroad is extended by the takeover of a production facility in the Netherlands.

The production program is significantly expanded by the start of screw compressor production. This sets the course for a successful future in compressor manufacturing.

In 1990, the German entrepreneurial family Dr. Dieter Murmann acquired the shares of ALUP. The parent company J. P. Sauer und Sohn Maschinen Beteiligungsgesellschaft mbH in Kiel thus supplemented its previous activities in the high-pressure compressor sector with the low- and medium-pressure segment.

The screw compressors manufactured in Köngen are also to be used on ships. There, special demands are made on the reliability and durability of compressors. In 1994, the first screw compressor for ship operation is accepted by the classification society Germanischer Lloyd. Since then, more and more ships worldwide have been equipped with marine compressors from Köngen.

In order to make the screw compressors even better and more efficient and applicable in even more industries, variable speed control as well as water-injected systems were included in product development in the 1990s. As a result, the first 100% oil-free, water-injected screw compressor with a unique concept was launched in 1992. These compressors are particularly important in sensitive areas such as the food and beverage industry and in medical technology.

In 1998, the first compressor series with speed control was developed. By precisely adapting the volume flow to the respective compressed air requirement, costly idle times are reduced to a minimum and energy is saved.

At the beginning of the 2000s, the product range is expanded to include compressors for railroad and rail transport. Special safety regulations apply to this sector and reliability has a particularly high priority. The compressors must be able to withstand temperatures ranging from +40°C in summer to -20°C in winter without any problems.

After a change of ownership, the newly founded ALMiG Kompressoren GmbH officially starts operations on 01 July 2007. The name ALMiG means Automatische Luftpumpen (Automatic Air Pumps) - Made in Germany.

Since 2012, the traditional Swabian company has been part of the multinational Fusheng Group.

Founded in 1953, Fusheng Group is the parent company of ALMiG, which specializes in manufacturing a wide range of products from air compressors to golf club heads to semiconductor lead frames. The group has approximately 16,000 employees in 25 locations and ~$1. billion in sales.

The company is managed by Viktor Weber. ALMiG Kompressoren GmbH employs around 300 people and still produces almost all of its compressors in Germany, at the same location as it did back in 1923.

Today, ALMiG is not only a successful supplier of compressors, but also offers customized systems for the generation and treatment of compressed air.