In a compressor, atmospheric air is usually brought to a higher pressure potential by adding mechanical energy. The enclosed air molecules are pressed closer together, "compressed", by reducing the space.

In screw compressors, the ambient air is compressed into compressed air by rotors. Screw compressors belong to the group of rotary compressors, the most important category of positive displacement compressors.

Screw compressors are equipped with two spindle-shaped intermeshing rotors. The main rotor converts approximately 85 - 90% of the energy absorbed at the coupling of the drive unit into pressure and heat energy. Together with the main rotor, the auxiliary rotor ensures that a compression chamber is formed between the suction and discharge sides.

During compression, progressive rotation of the rotors closes the air inlet opening and reduces the volume as the pressure increases. At the same time, oil is injected into the system for lubrication, sealing and heat dissipation.

How screw compressors work

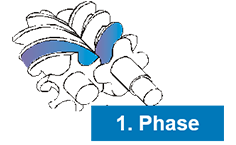

1st phase

Air enters the compressor housing through the inlet port.

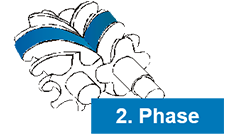

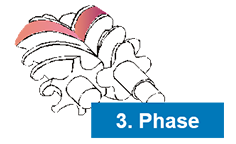

2nd and 3rd phase

When the rotors have rotated past the inlet port, they form a sealed compression chamber between the threads and the housing. This is reduced in size by the rotational movement of the rotors, and the enclosed air is compressed.

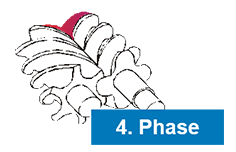

4th phase

The compressed air flows out Compression final pressure: max 15 bar (g)

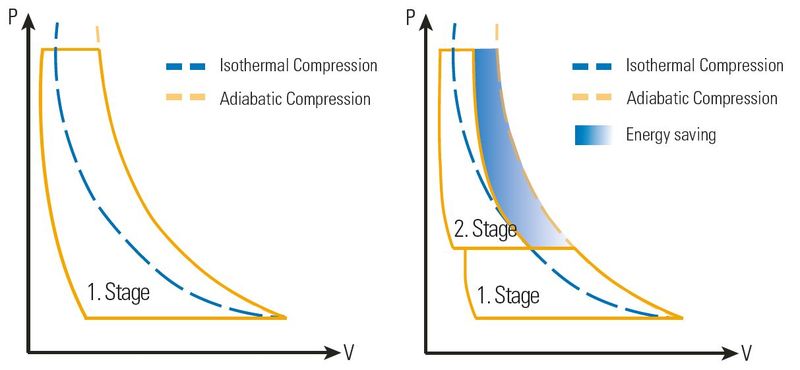

The main difference of two-stage compression from single-stage compression is that in two-stage compression the compression process is divided into two stages. After compression in the first stage, the air is intercooled. Then, in the second compression stage, the air is compressed to the final pressure.

The compression process is close to isothermal compression, which means that the outlet temperature is almost the same as the inlet temperature, thus avoiding energy losses. With two-stage compression, the pressure differences in the individual stages are smaller. This reduces leakage losses.

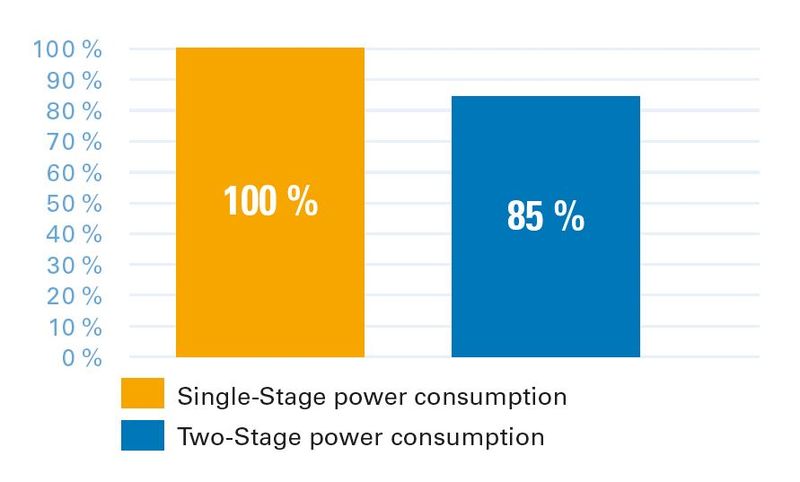

Overall, two-stage compressors consume between 11% and 15% less energy than single-stage compressors of comparable size.

Nearly isothermal compression

When air is compressed, it is strongly heated - depending on the compression principle, temperatures of up to 200°C are generated. The heated compressed air must be cooled down before it can be leased into the compressed air lines.

With two-stage compression, the air is heated less, so the compression temperature is lower. Due to the lower compression temperature, the heated compressed air does not have to be cooled as much before it is fed into the lines.

Thus, less energy has to be used for cooling.