How does the world's most enAIRgy-efficient screw compressor become even more efficient? You combine the highly efficient two-stage compression with speed control.

ALMiG combines exactly that in the V-Drive T screw compressor series!

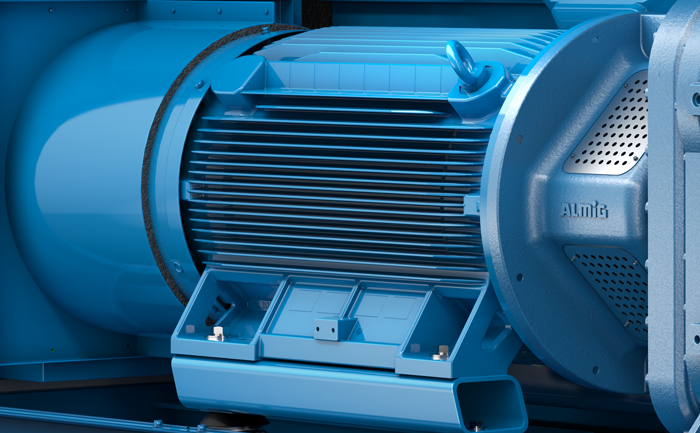

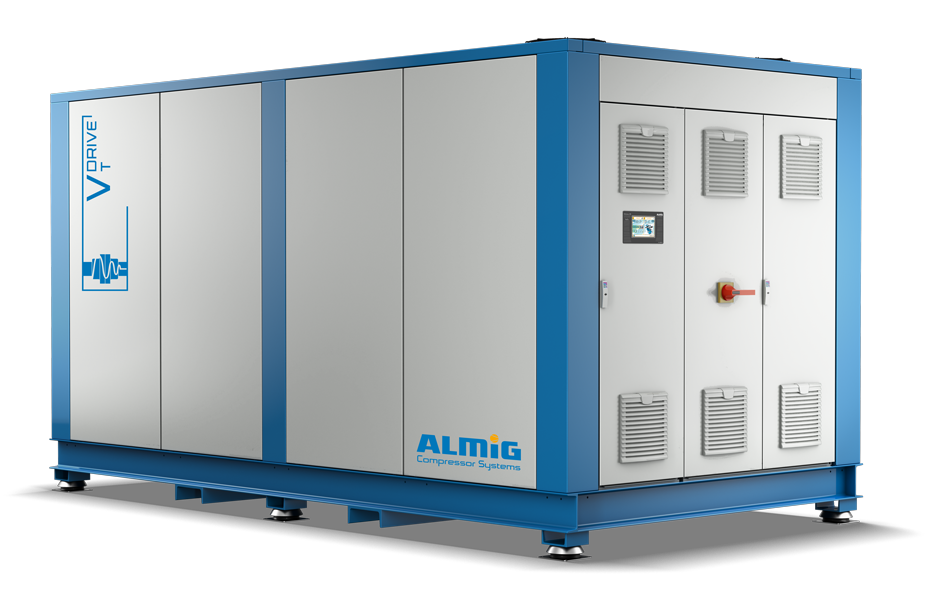

Compressor series V-Drive T

The unique stage design integrates the first and second stages in one compressor unit. The rotors of each compressor stage reach the optimum speed through the gear drive.

Efficient compression is achieved by using a cooling oil mist for intercooling. This controlled amount of oil simultaneously prevents the pressure dew point from being undershot in order to exclude condensate failure in the second compressor stage.

Advantages:

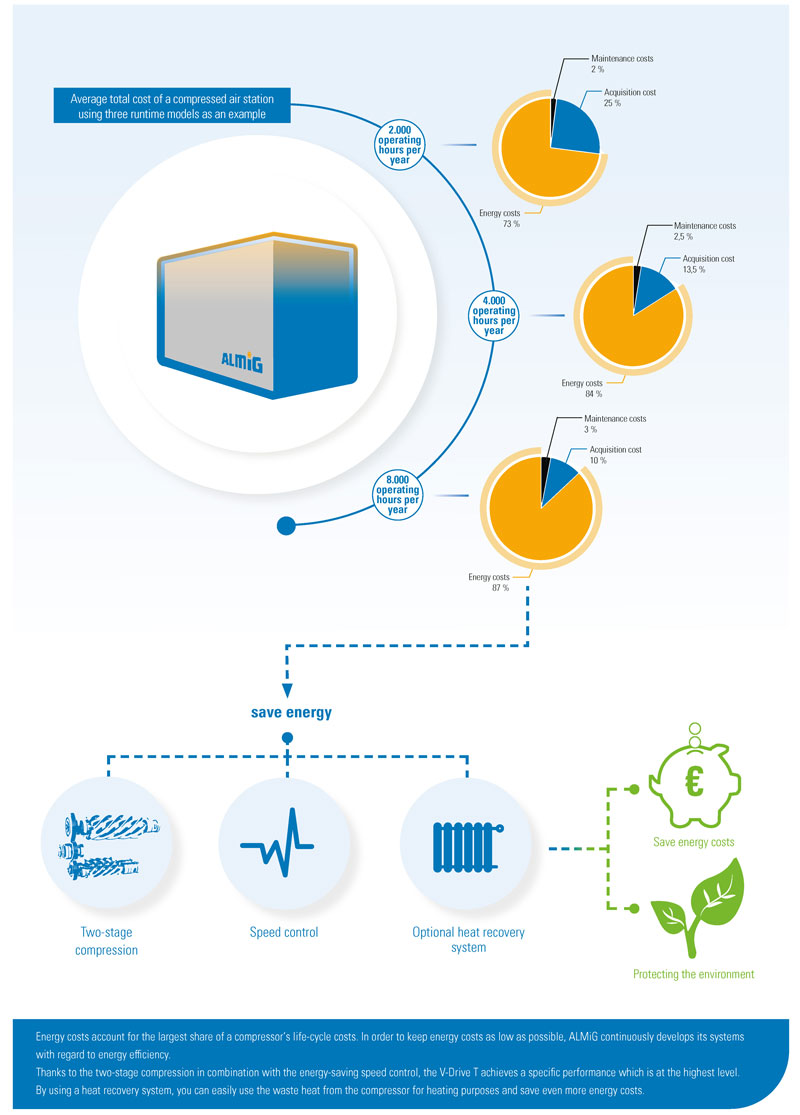

- Due to the high efficiency of the compressor, high energy savings can be achieved and the life cycle costs of the system can be reduced.

- In some cases, far more than 10 % energy savings compared to single-stage compression.

- No expensive idle times due to compressor speed control

- Durable and reliable

- Low differential pressures

- Low heat load

- Easy maintenance and service

Inconvenient and expensive separate intercooling can be avoided and reliability is increased at the same time.

By controlling the speed and varying the motor speed, the delivery rate is automatically and sensitively adjusted to the fluctuating air consumption. This reduces costly and energy-intensive idle time to a minimum. Low speeds and a lower internal pressure difference in each stage also increase the service life and reliability of the compressor unit in addition to efficiency.

Technical information

V-Drive T | Volume flow according to ISO 1217 (Annex C-2009) | Rated motor power | Length | Width | Height | |

|---|---|---|---|---|---|---|

Model | min. | max. | kW | mm | mm | mm |

| 20 | 9.7 | 19.5 | 90 | 3250 | 1800 | 1868 |

| 24 | 9.7 | 23.5 | 110 | 325 | 1800 | 1868 |

| 28 | 9.7 | 27.7 | 132 | 3881 | 2250 | 2438 |

| 34 | 12.5 | 34.6 | 160 | 3881 | 2250 | 2438 |

| 42 | 13.1 | 42.1 | 200 | 4531 | 2250 | 2438 |

| 52 | 14.4 | 53.1 | 250 | 4531 | 2250 | 2438 |

| 64 | 12.5 | 62.0 | 315 | 4531 | 2250 | 2438 |

![ALMiG V-Drive T screw compressors [Translate to English:] ALMiG Schraubenkompressoren V-Drive T](/fileadmin/user_upload/Produkte/Schraubenkompressoren/V-Drive_T/ALMIG_G-Drive_T315_offen.png)