The basic components of a screw compressor include the rotors, the housing, the inlet, the outlet and the compressor control. The rotors are the main components that compress the air. They are usually made of steel or aluminium and have specially profiled, helical cams that interlock. The rotors are housed in a casing that contains the air and prevents it from escaping during compression.

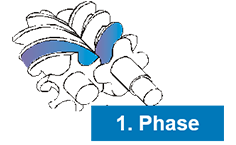

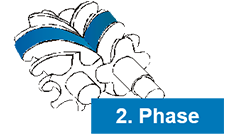

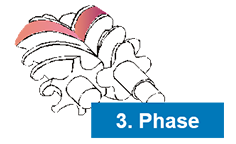

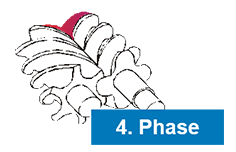

Ambient air is drawn in through an intake regulator and is compressed as it passes through the rotor chambers. As the rotors turn, the air is trapped between the rotors and compressed on its way to the discharge opening. At the discharge port, the compressed air leaves the compressor and is sent to the next stage of the compressed air system (e.g. a refrigeration dryer).

The control system of a screw compressor is responsible for regulating the air output and controlling the operating conditions of the compressor. This includes monitoring the temperature, pressure and oil level of the compressor to ensure optimum performance and prevent damage.

There are two types of screw compressors: oil-injected and oil-free. Oil-injected screw compressors use oil to lubricate the rotors and cool the compressed air, while oil-free screw compressors rely on special coatings and materials for lubrication and cooling.

In a nutshell, screw compressors work by trapping air between two interlocking screws and compressing it as the screws turn. They are a reliable and efficient option for businesses that require compressed air and offer customisable options to meet specific air needs.

Advantages of screw compressors

One of the main advantages of screw compressors is their efficiency.

Compared to other types of compressors, such as piston compressors, screw compressors require less energy to operate. This means lower operating costs and lower energy consumption.

Another way to save energy when operating screw compressors is to use speed-controlled compressors. These only draw as much power as is actually required to generate the required amount of compressed air. In addition, costly idle times are reduced to a minimum by precisely adjusting the volume flow to the respective compressed air requirement.

Heat recovery is also a significant factor that can be used with screw compressors to save energy costs for room heating, for example.

Another advantage of screw compressors is their reliability

Screw compressors have fewer moving parts than other compressors, which reduces the risk of breakdowns and minimises maintenance costs. They are also less sensitive to changes in air demand, so they can maintain a constant air output even under variable operating conditions.

Screw compressors provide a reliable and efficient means of producing compressed air for businesses that require it.